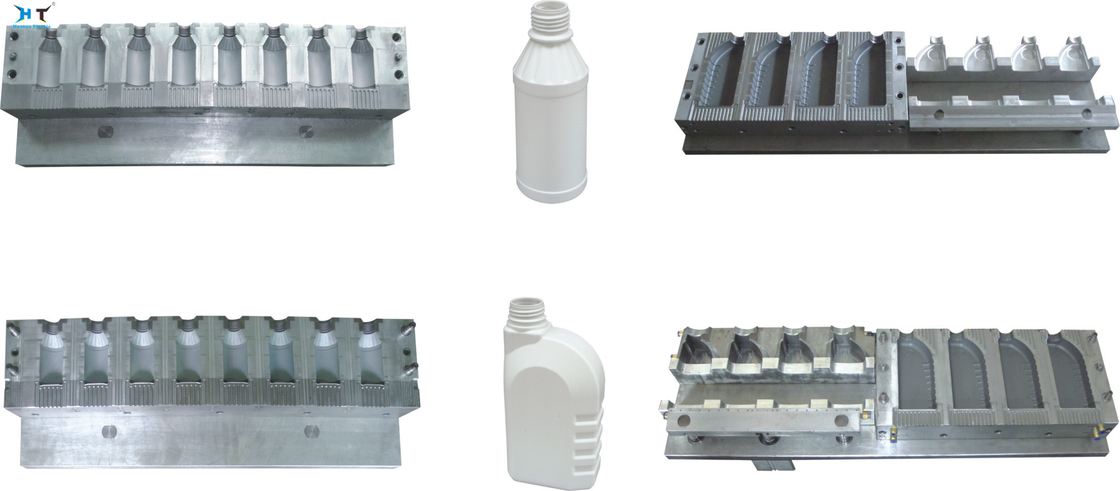

Automatic Deflashing Multi Cavity Customized Plastic Milk Juice Bottle Blowing Mould

| Technique |

Automatic Deflashing Multi Cavity Customized Plastic Milk Juice Bottle Blowing Mould |

| Surface treatment |

Polishing, or as customer's requirements |

| Material |

Mold: 718H, S136H, NAK80, DIN1.2344, LKM2083, LKM2344, 8406, 8407, S136, LKM2767 etc.

|

| General size |

According to your 3d drawings or samples |

| Design software |

UG, PROE, CAD, CAXA etc |

| Plastic mould life |

500,000 shots |

| Manufacturing Machines |

CNC,EDM,MILLING,WIRE-CUT, etc |

| Runner |

Cold runner |

| Design Software |

UG,PROE,CAD, Solidworks, etc |

Cavity number of mould

|

Single cavity, Multiple cavity or one mold with different products |

| Surface treatment |

Words corrosion, Mirror polish, Frosted surface or textured surface |

| Mould standard |

Domestic standard, HASCO standard, DME standard. Master flow standard |

| Mould testing |

All of the moulds can be well tested before the shipments. |

| Good packages |

In strong wooden pallets to avoid any damages during the long |

Main Features

1. Capacity: We make mould as your customed. We can design bottle for you.

2. Good quality and competitive price.

3. Size:From 0.1L to 25L.Mould Material:#45 or 7075 Al

4. Blow molding processing.

5. Logo and label can be printed.

6. We can manufacture products according to your picture or samples

Application:Minaral water,juice,carbonated drink,oil,food,honey,alcohol and cosmetic bottles and hot filling bottles.

Suitable for different kinds of machine,Including semi automatic machine and full automatic machine

.

High classic very mature bottle mould structure, The application of strong steel leads to best cooling effect, best chinese hot runner professional filter system design, suitable for high speed recycled material injection production.

Our Mould Features:

| 1. |

Rotational mould design, reduce production cycle time; |

| 2. |

Mirror hand polishing, create added value; |

| 3. |

Full automatic, high efficiency; |

| 4. |

Fine cooling system, fine parting effect; |

| 5. |

International standard, durable mould life. |

Mold Service:

| Quotation |

Fast reply, in 2 working days |

| Pre-production proposal |

We offer professional & practical solution for your investment |

| OEM/ODM service |

We would provide OEM/ODM service as customer’s need |

| Mold process report |

Weekly report, mold trial video and samples for your checking |

| Approval |

2D/3D mold drawing & mold manufacturing schedule for customer’s approval |

| Written warranty |

Steel certificate, mold trial report, parts measuring report, operating instructions, maintenance specifications |

| Spare parts |

wearing spare parts provided |

| After sale service |

Provide |

| Communications |

email, phone, Trade Manager, Msn, Skype,We-chat |

FAQ

Q1:What kind of moulds do you make (plastic injection,compression or somethirelse)?

We are specialized in Plastic Injection mould , blow mould,and we can help customers arrange sourcing for other moulds.

Q2:Do you build hot runner plastic mould?

Yes,We bulid hot runner plastic moulds and specialized in many different systems,such as DME,Master Mastip,Hasco,Yudo,Incoe,Husky,etc.We can meet your special needs.

Q3:How long is the lead-time for a plastic injection mould?

It all depends on the mould's size and complexity,normally,the lead time is 40days

Q4:Do you make spare parts for your cunstomer?

Yes,we can provide spare parts for mould if necessary or required by customers

Q5:How do you protect your moulds during packaging?

We protect our moulds by ueing anti-rust oil and wrapping film.To prevent damage during transition,We pack all moulds in wooden boxes.

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!