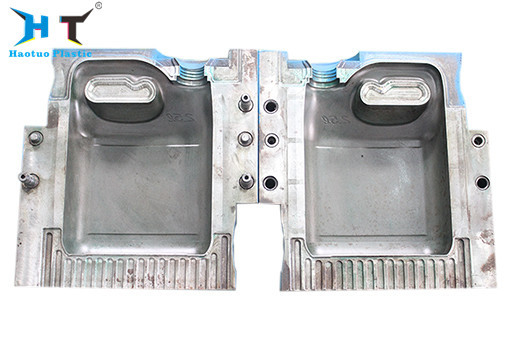

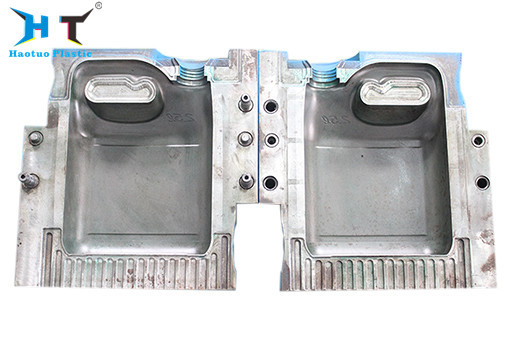

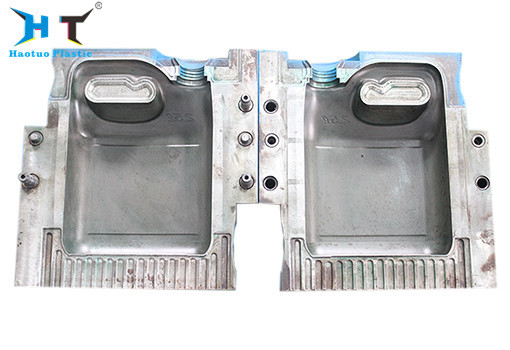

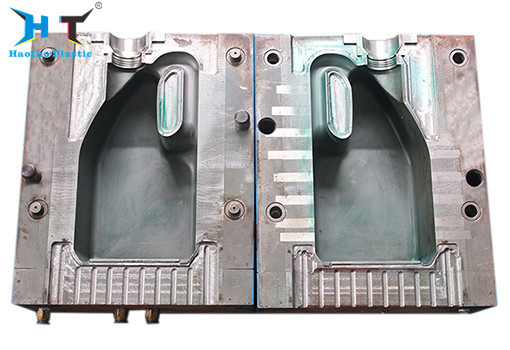

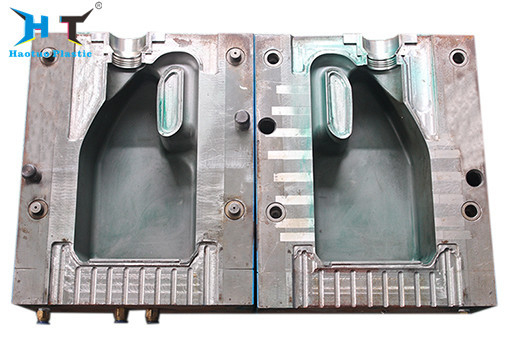

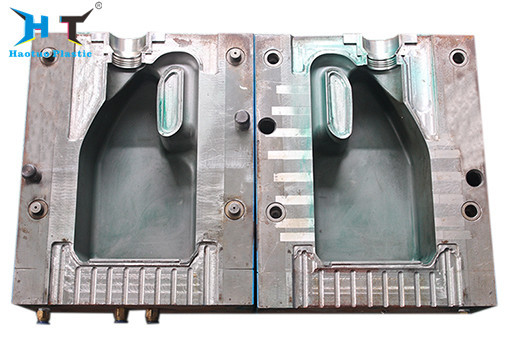

Professional Design oil Bottle Blow Molding Mold Precision Plastic Bottle Mould

| Technique |

Plastic blowing Mould |

| Surface treatment |

Polishing, or as customer's requirements |

| Material |

Mold: 718H, S136H, NAK80, DIN1.2344, LKM2083, LKM2344, 8406, 8407, S136, LKM2767 etc.

|

| General size |

According to your 3d drawings or samples |

| Design software |

UG, PROE, CAD, CAXA etc |

| Plastic mould life |

500,000 shots |

| Manufacturing Machines |

CNC,EDM,MILLING,WIRE-CUT, etc |

| Runner |

Cold runner |

| Design Software |

UG,PROE,CAD, Solidworks, etc |

Cavity number of mould

|

Single cavity, Multiple cavity or one mold with different products |

| Surface treatment |

Words corrosion, Mirror polish, Frosted surface or textured surface |

| Mould standard |

Domestic standard, HASCO standard, DME standard. Master flow standard |

| Mould testing |

All of the moulds can be well tested before the shipments. |

| Good packages |

In strong wooden pallets to avoid any damages during the long |

Mould Feature

Excellent machinical strength. impact-resting,and non-cracking.Bottle mouth and screw thread are of precise measurement, enable 100%

close matching with the bottle cap.The weight of the product can be pre-setted.The measurement and thickness of the product can meet the requirement of design without any deviation.The surface of bottle mouth and body is bright and smoonthness. No defleshing and trimming save the material cost.There is no joint seam at the bottom, and strength is improved accordingly. The joint seam on the bottle body is smooth.

Blowing Oil Barrel /Jerrycan/Petrol Specification

1.One cavity or more than one cavity

2.Mould material used 50#,P20,2316,S136,MgAl

3.with deflashing or not

After-sales service:

1)

1.Provide 1 year of technology service after mould delivery.

2.Provide mould spare parts within 1 year after mould delivery.

3.Provide mould maintenance free of charge within 1 year after mould delivery.(Except of man-made damage).

4.Provide 3 years of maintenance service after warranty period (collect appropriate cost).

5.If the mould problem is caused by human reasons, we will change an appropriate cost for maintenance.

.

FAQ

Q1:What kind of moulds do you make (plastic injection,compression or somethirelse)?

We are specialized in Plastic Injection mould , blow mould,and we can help customers arrange sourcing for other moulds.

Q2:Do you build hot runner plastic mould?

Yes,We bulid hot runner plastic moulds and specialized in many different systems,such as DME,Master Mastip,Hasco,Yudo,Incoe,Husky,etc.We can meet your special needs.

Q3:How long is the lead-time for a plastic injection mould?

It all depends on the mould's size and complexity,normally,the lead time is 40days

Q4:Do you make spare parts for your cunstomer?

Yes,we can provide spare parts for mould if necessary or required by customers

Q5:How do you protect your moulds during packaging?

We protect our moulds by ueing anti-rust oil and wrapping film.To prevent damage during transition,We pack all moulds in wooden boxes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!