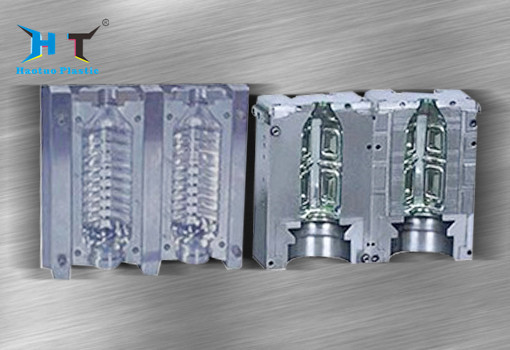

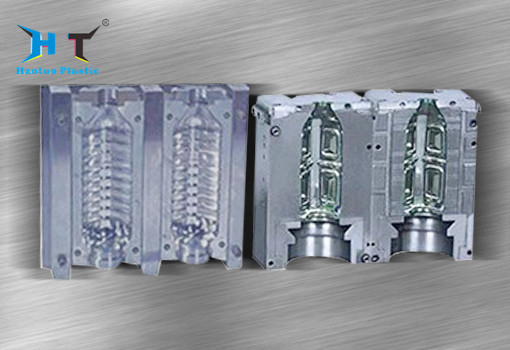

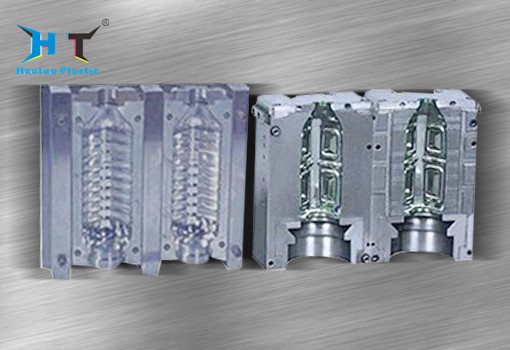

Multi Cavities PET Plastic Bottle Blow Mould Soft Drink Bottle Mold

| Technique |

Multi Cavities PET Plastic Bottle Blow Mould Soft Drink Bottle Mold |

| Surface treatment |

Polishing, or as customer's requirements |

| Material |

Mold: 718H, S136H, NAK80, DIN1.2344, LKM2083, LKM2344, 8406, 8407, S136, LKM2767 etc.

|

| General size |

According to your 3d drawings or samples |

| Design software |

UG, PROE, CAD, CAXA etc |

| Plastic mould life |

500,000 shots |

| Manufacturing Machines |

CNC,EDM,MILLING,WIRE-CUT, etc |

| Runner |

Cold runner |

| Design Software |

UG,PROE,CAD, Solidworks, etc |

Cavity number of mould

|

Single cavity, Multiple cavity or one mold with different products |

| Surface treatment |

Words corrosion, Mirror polish, Frosted surface or textured surface |

| Mould standard |

Domestic standard, HASCO standard, DME standard. Master flow standard |

| Mould testing |

All of the moulds can be well tested before the shipments. |

| Good packages |

In strong wooden pallets to avoid any damages during the long |

Main Features

1. Capacity: We make mould as your customed. We can design bottle for you.

2. Good quality and competitive price.

3. Size:From 0.1L to 25L.Mould Material:#45 or 7075 Al

4. Blow molding processing.

5. Logo and label can be printed.

6. We can manufacture products according to your picture or samples

Application:Minaral water,juice,carbonated drink,oil,food,honey,alcohol and cosmetic bottles and hot filling bottles.

Suitable for different kinds of machine,Including semi automatic machine and full automatic machine.

Process of PET blow mould

1. Sample or 3D Drawing Provided by Client(According to 3D design or samples for quotation)

2. Negociations ( About the price of mould, the size of the mold, and material.send quotation for you)

3. Product 3D Design ( Our experienced engineers and designers make the 3D design for you)

4. Design Confirmed (Confirm the drawing and mould material, and other detials with custmer)

5. Mould Making (Purchase mold base and metarials,Use CNC, EDM machine,assembly mold etc.)

6. Tryout Mould ( Trial 10 samples)

7. Inspect Samples ( Our engineers inspect the detail of sample)

8. Sample Sending and Confirmed (Send about 10 samples for customers)

9. Mass Production (After confirm the samples)

10. Delivery(Shipping by sea or by air)

About us

We are a professional plastic mold and plastic machine manufacturer, with the strength of manufactured with good quality and pretty competitive price.

We can tailor various kinds of Mould for each customer as per their requirements.

The quotation can be made based on drawings or samples provided by the customers.

Our products are both excellent in quality and reasonable in price.

Your satisfaction is guarantee.

Engineering capabilities include:

1.Parts design

2.R&D products

3.Prototype design and production assembly

4.Reputable design software used for all design work

5.Fast automatice remould design

6.Mould design with a team of experienced specialists

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!